Solution Deployment Method

At Artifex International Consulting Group, we understand that every Automation project in the Supply Chain, Manufacturing, Pharmaceutical, SMT Electronics PCB, Automotive, Biotechnology.

Our approach is based on a structured process to ensure success from initial design to final implementation. Below we outline the key stages of our deployment method:

Improve your team's productivity

Streamline your workflow with our RAG platform and get accurate answers quickly and easily.

How Our Solutions Work

Recovery Augmented Generation (RAG):

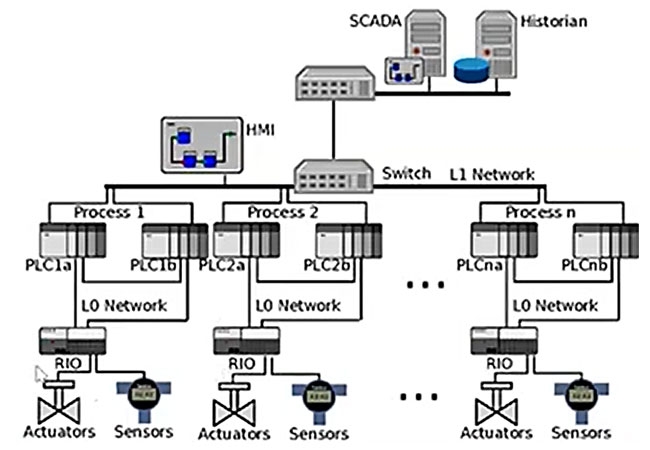

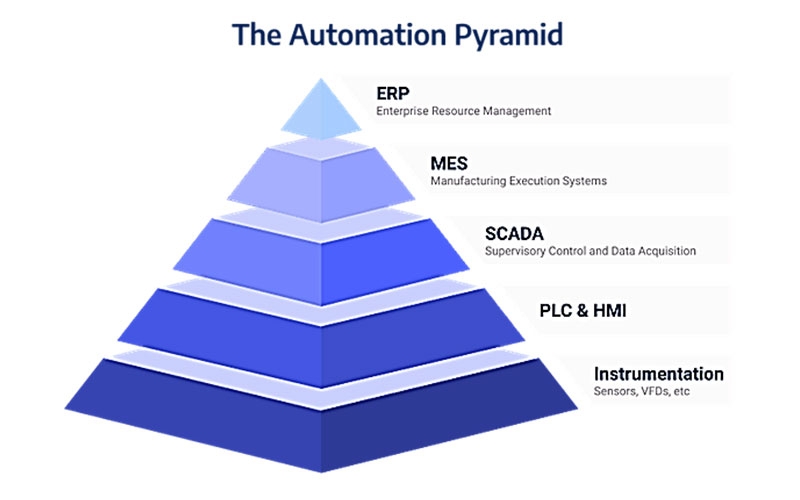

In SCADA and MES systems, combining specific data retrieval with detailed reporting facilitates deeper analysis and the generation of coherent and contextual reports, optimizing the monitoring and control of industrial processes.

IIoT, IoMT, SCADA, MES:

It combines different models and technologies to offer customized solutions that improve operational efficiency and connectivity between devices.

Large Language Models (LLMs):

These advanced models enable fluid text processing and generation, providing support in the generation of scientific reports, article writing and complex data analysis.

Machine Learning Techniques:

We implement machine learning algorithms to analyze IIoT and IoMT data, identify operational patterns, and make accurate predictions. This allows us to optimize the performance of industrial processes, predict failures, and improve real-time decision making.

Integration into your own business system

Our Commitment

We are committed to resource optimization, project scalability and the use of advanced technologies. We use innovative techniques for industrial processes as well as for biotechnology, giving access to historical data through the OPC HA interface. OPOC tag, OPC UA controlled by PID.

- Traceability.

- Data Integration and Security.

- Electronic Records Management.

- Data Access Control by organizational rules.

Challenges of Recovery Augmented Generation (RAG) in IIoT and SCADA Environments

Recovery Augmented Generation (RAG) improves the performance of IIoT, IoMT and SCADA systems,:

IoT Systems:

Profile analyses of data acquisition systems, LoRa, WIFI, Arduino, ESP32, Raspberry are performed.

Fine-tuning complexity:

Tuned data acquisition architectures are secured with AKS, Docker to maintain persistence.

Data quality and bias:

The data is analyzed from the data acquisition profile, verifying the Divergence, Convergence and Stability of the devices, and also verifying the Repeatability and Reproducibility, considering whether the system has Autocorrelation or is Random.

Lack of evaluation metrics:

The quality of the data retrieved translates into more accurate and useful answers. We work to ensure that the data is unbiased and of high quality, maximizing the effectiveness of the responses generated.

Our Objective

We support our clients in each of the following stages:

- 1.- Design Proof of Concepts - Adapted to your priorities.

- 2.- Plan the Proof of Concept (POC) in Detail - To validate feasibility.

- 3.- Implement the MVP Solution - Focused on essential functionalities.

- 4.- Track and Optimize Results in Production (DevOps) - Continuous improvements and updates.

- 5.- Turnkey design - We carry out detailed engineering, mechanics, pneumatics, electricity, automation, process simulation, and material flow design.

Support in Implementations

Are you interested in controlling a manufacturing, biotechnology, pharmaceutical, automotive, logistics process, or supporting CONACYT PEI programs? Would you like to receive PEI support to improve your processes? Select all the areas that apply:

- Network layout planning - Voice/Data LAN.

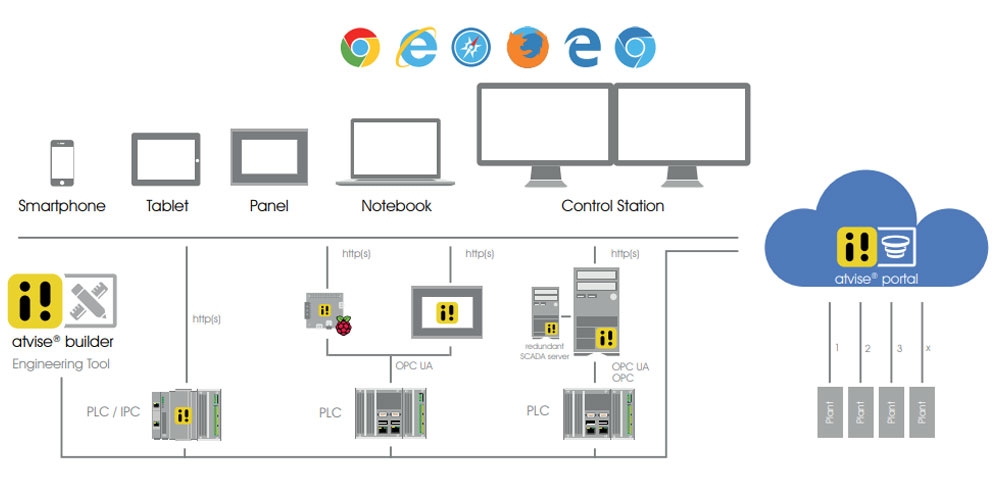

- Communications planning - Application of OPC UA, MQTT, AMQT, RabitMQ, Pulsar, Kafka Protocols.

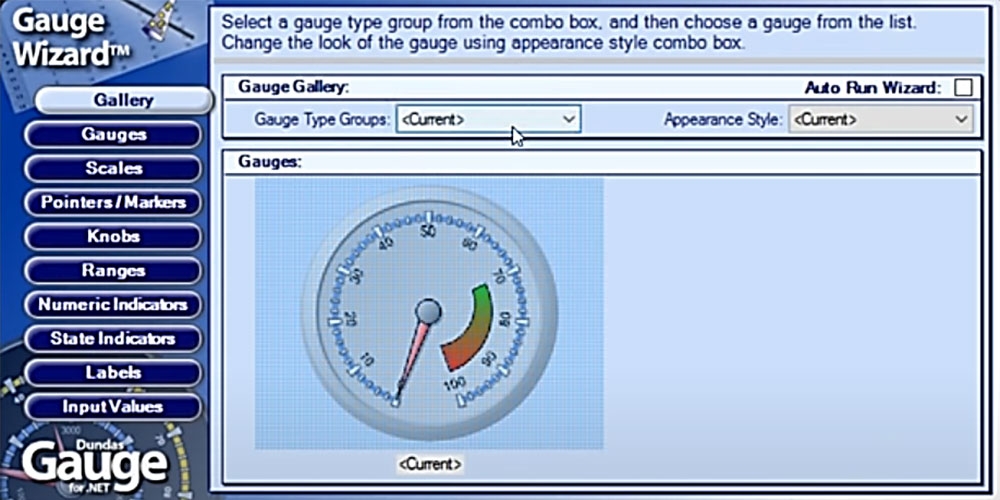

- Monitoring planning - Digitalization interface design – HMI, SCADA, OEE + MES, Vision Comp.

- Control system design - Creation and advancement of innovative technologies.

Services Offered

Implementation of IoT Solutions in the Cloud: Configuration and deployment of IoT platforms in Azure to collect, store and analyze data from connected devices in real time, optimizing visibility and control of industrial operations.

Integrating SCADA Systems with Azure IoT: Development of interfaces and solutions that connect existing SCADA systems with Azure IoT to improve monitoring and control of industrial processes using real-time data.

MES (Manufacturing Execution System) Application Development: Implementation of Azure-based MES solutions to manage and optimize production, from planning to execution, integrating real-time data with IoT platforms.

Process Automation and Control with IIoT: Design and execution of industrial automation strategies using IIoT, integrating sensors and smart devices to improve operational efficiency and decision making in the plant.

Predictive Analysis and Preventive Maintenance: Implementation of Machine Learning models in Azure for predictive analysis of IoT data, enabling early identification of faults and scheduling of preventive maintenance.

IoT Data Security and Governance: Development of security and governance strategies to protect data generated by IoT devices, ensuring the integrity, confidentiality and availability of information in compliance with regulations.

Consulting for IoT Infrastructure Optimization: Consulting services to assess and optimize existing IoT infrastructure, recommending improvements in hardware, software, and cloud architectures to maximize performance and scalability.

ESP

ESP  ENG

ENG